Underfloor heating is a great way to heat your home, but if you have never done it before it can be difficult to figure out how much power you'll need for this project.

The good news is that it’s not as complicated as you might think! We’ve created this guide to help breakdown what best floor heating system for DIY projects as well as electrical requirements needed.

There are two different types of underfloor heating: Hydronic and Electric. Hydronic is a water based system that you will need a professional to install. So if you are wanting to install floor heating yourself the best option is electric floor heating mats.

When choosing underfloor heating mats there are two options:

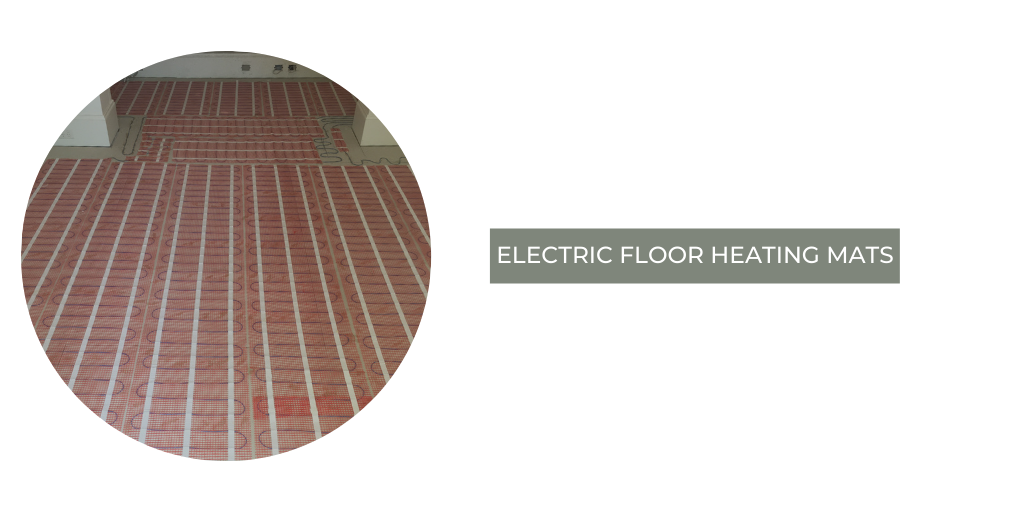

1. Under Tile floor heating:

Application:

- Heating directly under tile, in tile glue or within thin leveling screeds ≤ 20mm

- Combine multiple mat heaters to achieve required heated floor area in larger rooms

- Best choice for residential & commercial floors requiring fastest response times

Our Under Tile Mat adds no significant height to floor levels, making it the ideal choice for flooring installations where no screed topping is required. The FHK mat design also offers a reduced installation time and does not require special tools or skills to plan their layouts.

2. In Screed floor Heating:

Application:

- Heating directly under tile, in tile glue or within thin leveling screeds ≤ 40mm

- Suitable for majority of floor finishes, including stone, ceramic tiles, slate, porcelain, limestone, marble, terracotta and more.

- Designed to be installed directly on the existing sub floor or on top of waterproofing. The screed layer is then applied on top of the heaters and floor finish is laid over the top of the screed.

- Best choice for residential & commercial floors (including bathrooms)

Our In Screed Mat's unique mat design features a traditional style twin in-screed floor heating cable pre-attached to a nylon mat with tape strips for fixing to a clean substrate. The fabricated mat heater offers a reduced installation time. And removes the need for steel mesh, cable &/or floor fixings and the risk of hot and cold spots across floor as a result of inconsistent spacing of loose heating cables.

These mat heaters offer a faster warm up time when compared to most in-screed & in-slab systems due to it’s high performing output to warm floors faster and reach standby heat cycles in a more timely manner. Under performing floor heating systems of lower wattage rarely reach set points within programmed time schedules, often requiring earlier start times to reach temperatures close to comfort levels resulting in overall higher running costs.

3. Under Carpet Floor Heating

Application:

- Laminate Panel 14 is designed for installation directly under carpet on top of the underlay.

Our Laminate Panel 14 Thin Cable Mat has been designed and developed to exceed all relevant standards, ensuring installation is quick and simple. Experienced product design ensures minimal increase to existing floor levels with an even heat across the complete floor surface.

The aluminium foil that forms the outer casing of the panel is waterproof and in addition to aiding in the even spread of heat, protects the Teflon heating element which is sandwiched between the aluminium foil. The heating element is of special design using materials carefully selected for an optimum balance of performance and safety with overheat protection. The heating element connects to a 6 metre long power-supply cable which exits the heating mat from one corner.

ELECTRICAL REQUIREMENTS

Now let’s take a closer look at the electrical requirements: Before installing an Under Tile Mat heater you should make allowance for the electrical connections.

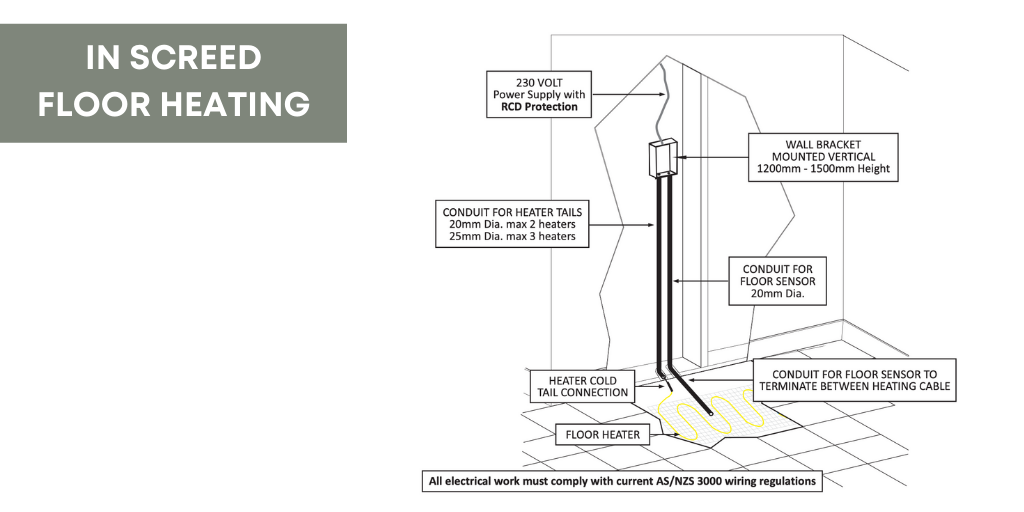

Underfloor heating can be DIY installed but must be commissioned by a licensed electrical contractor who will connect the Thermostat to the heater & mains supply on an RCD to comply with current AS/NZS 3000 wiring regulations.

Our In Screed and Under Tile Mat heaters require a mains voltage 230V supply and must be connected to an approved Residual Current Device (RCD). It is recommended you consult with your electrician to ascertain whether or not the circuit and cabling can handle the additional load and if a RCD is protecting the circuit.

If connecting multiple heating mats with an electrical load greater than 16A to one thermostat, you will require a suitably sized electrical contactor.

In Screed and Under Tile Floor Heating Mats are supplied with a single cold tail lead which should run from the floor to the thermostat in a single 20mm conduit (limit 2 heating mats per 20mm conduit). A separate conduit is required to be extended and positioned to lay between two heating cables, for the thermostat floor sensor.

Once you have decided which system to go with, the next step is to work out how much is needed for each room. We have compiled a step by step guide on how to measure for underfloor heating. (Click here for step by step guide)

So if you're considering installing underfloor heating in your home, it's important to know a few things.

First of all, what type of flooring are you going to install and under what kind of surface. Secondly, consult with an electrician to ascertain whether or not the circuit and cabling can handle the additional load and if a RCD is protecting the circuit.

To view our different size kits available for different types of underfloor heating kits click the links below.

Under Tile Systems:

Living Rooms or Bedrooms

Bathrooms

In Screed Systems:

Designed to be installed directly on the existing sub floor or on top of waterproofing. The screed layer is then applied on top of the heaters and floor finish is laid over the top of the screed.

In Screed Mat for Bathrooms

In Screed Mat for Living & Bedrooms

Under Carpet Floor Heating

Laminate 14 Panel Under Carpet Heating

If you have any questions our extra friendly staff are but a phone call away. Contact us on: (02) 9114 6934